The principle and structure of the car camera

2022-08-19 Author:BRVISION

The principle and structure of the car camera

The advanced nature of automobiles is mainly reflected in the aspects of convenient driving, energy saving and environmental protection. With the improvement of the country’s requirements for automobile environmental protection and energy saving and the expectations of drivers for vehicle performance and technological content. Various electronic configurations of the car came into being, and CMS, ADAS and autonomous driving systems were all listed in the car configuration catalog. As the main external environment data acquisition sensor-camera of CMS, ADAS and automatic driving system, its importance is highlighted. Since the EU standard ECE-R46-2018 allowed the use of CMS on vehicles, the Chinese national GB15084-2013 standard has also been revised since June 2020 and is expected to be released within this year. Allowing CMS to be used alone on vehicles will included in the standard. This means that the demand for in-vehicle cameras, the main component of CMS, will explode after 2023. Become a new blue ocean industry in the auto parts industry.

Although there is a huge potential market in China, and the car camera market also has a wide range of applications, many manufacturers of security cameras have switched to car cameras, but the packaging technology and algorithms of car camera modules and the industry barriers to lens manufacturing at the automotive level , the setting of the overall system application scenarios of the camera, the core components of the camera industry chain, as well as the algorithm solutions, and the integration of other sensor technologies and other bottlenecks, the leading car camera manufacturers that can really be recognized by the car OEMs and not much. Therefore, whoever can break through the bottleneck first will reap the blue ocean.

The principle of car camera

The working principle of the car camera is that the optical image signal collected by the camera lens is transmitted to the CMOS image acquisition system and converted into an electrical signal, and then the electrical signal transmission module processes the signal and sends it to the display device. During the lens acquisition process, the control part of the CMOS image acquisition system of the lens will automatically adjust according to the external light conditions and the distance of the calibration object, so that the image effect collected by the camera can be adjusted to the best.

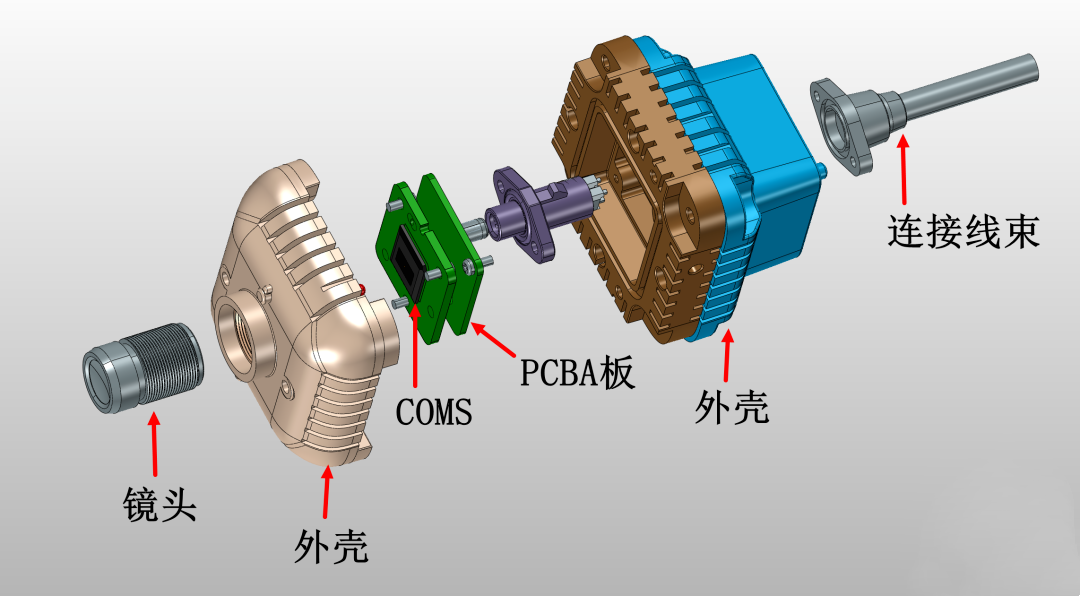

The structure of the car camera

As shown in the figure: The car camera is composed of lens, shell, COMS, PCB signal control board (module, shell and wiring harness.

Car camera lens material

At present, the lens of the car camera can be selected from various materials, such as glass, plastic resin and so on. The lens is processed by multiple groups of lenses for concave and convex surface angles, and the combination meets the requirements of optical design performance. The optical imaging quality and life are determined by the material. The material can be all-glass that can be protected for many years, or it can be a resin lens. Because the lens has transmittance requirements, the glass lens requires ultra-clear glass with a transmittance of more than 90%, and the processing requirements are relatively high and the cost is relatively high. Resin lenses are injection-molded by molds, and the cost is low, but they will be affected by external ambient light exposure and ambient temperature alternately, and most of them will turn yellow within 2-3 years. The resolution, distortion, stray light and ghost image, hydrophobicity and low-light imaging capability of the vehicle camera lens for the captured environment are high, and the temperature characteristics from -40°C to 85°C need to be guaranteed according to the requirements of vehicle-grade components. , so it generally adopts an all-glass + metal structure.

Vehicle camera lens coating process

A key process of the lens is the coating process. Due to the different components of the coating material, different functions, and different life spans, the price will vary greatly. A good coating material can reduce the reflectivity of the glass, improve the transparency of the glass, and can improve the image quality of the non-general coating materials. The coating process is also divided into cold plating and hot plating. Resin lenses are cold-coated, and the biggest difference between the two coatings is friction resistance and longevity.

Vehicle camera lens assembly process

In addition to lens manufacturing, lens assembly reflects the production process level of lens manufacturers, such as the tolerance of lens and lens barrel, lens fixation, imaging deployment, etc. The focus imaging process of high-quality, high-performance vehicle cameras is assembled with precision equipment.

Vehicle Camera COMS Selection

In-vehicle cameras are used as security components for intelligent and connected vehicles. Considering the complexity requirements of CMS and ADAS for the scene, higher requirements will be placed on the hardware statistics and algorithm processing of ISP signal processors, such as rainy days, foggy days, and high LX conditions during the day. , the image under low LX at night, the colorful reflection of objects around the vehicle, the illumination of the rear lights, etc. At present, many component suppliers in the market use security-grade CMOS chips for in-vehicle cameras, such as IVI central control display chips, devices in the field of DVR recorders, and even consumer security monitoring chips to realize the design of in-vehicle cameras. However, according to the effects of several models that have been mass-produced with CMS or ADAS, the traditional security-level chip solution does not perform well in the environmental image sampling targets of CMS and ADAS systems. For example, under the influence of complex light environment, the color cast, dark state noise, dispersion and ghosting, and the delay are large. So what factors should be considered in a CMS and ADAS solution that can really adapt to the actual vehicle environment, and the ideal chip solution for using a car camera is still to be discussed.

In a word, the market of vehicle-mounted cameras is a huge market in the future, and it is worthy of the efforts of manufacturers with development capabilities.

Previous:What is the best truck dash cam?

Next:【Technology】Application of vehicle-mounted monitoring system in dangerous goods transportation industry

Latest News

- Enhance Fleet Safety and Efficiency with the 2023 Iveco Daily Brake Light Camera2025-08-27

- See Clearly, Operate Safely: BRvision’s Heavy-Duty Camera Solutions2025-08-27

- 1TB Mobile SD video Recorder: The all-round guardian for security and driving2025-08-27

- New-generation 360 Degree Full HD Bird-View System2025-08-27

- Premium 7" Quad-Split Monitor for Superior Vehicle Monitoring2025-07-31

- Your Unbreakable 7" Vision Partner for Harsh Environments2025-07-31

- 9 INCH HD Quad Split Monitor2025-07-22

- Introducing the MNC04: Your Ultimate Compact Vision Solution for Tight Spaces!2025-07-22

- Tired of those nerve - wracking blind spots and constant visibility woes when operating trailers, mining trucks, or other heavy - duty construction vehicles?2025-07-22

- Brvision Makes Waves at Automechanika Istanbul 20252025-07-12

Copyright © 2025 Brivision-All rights reserved